Why is this important for you, no matter how big or small your company is?

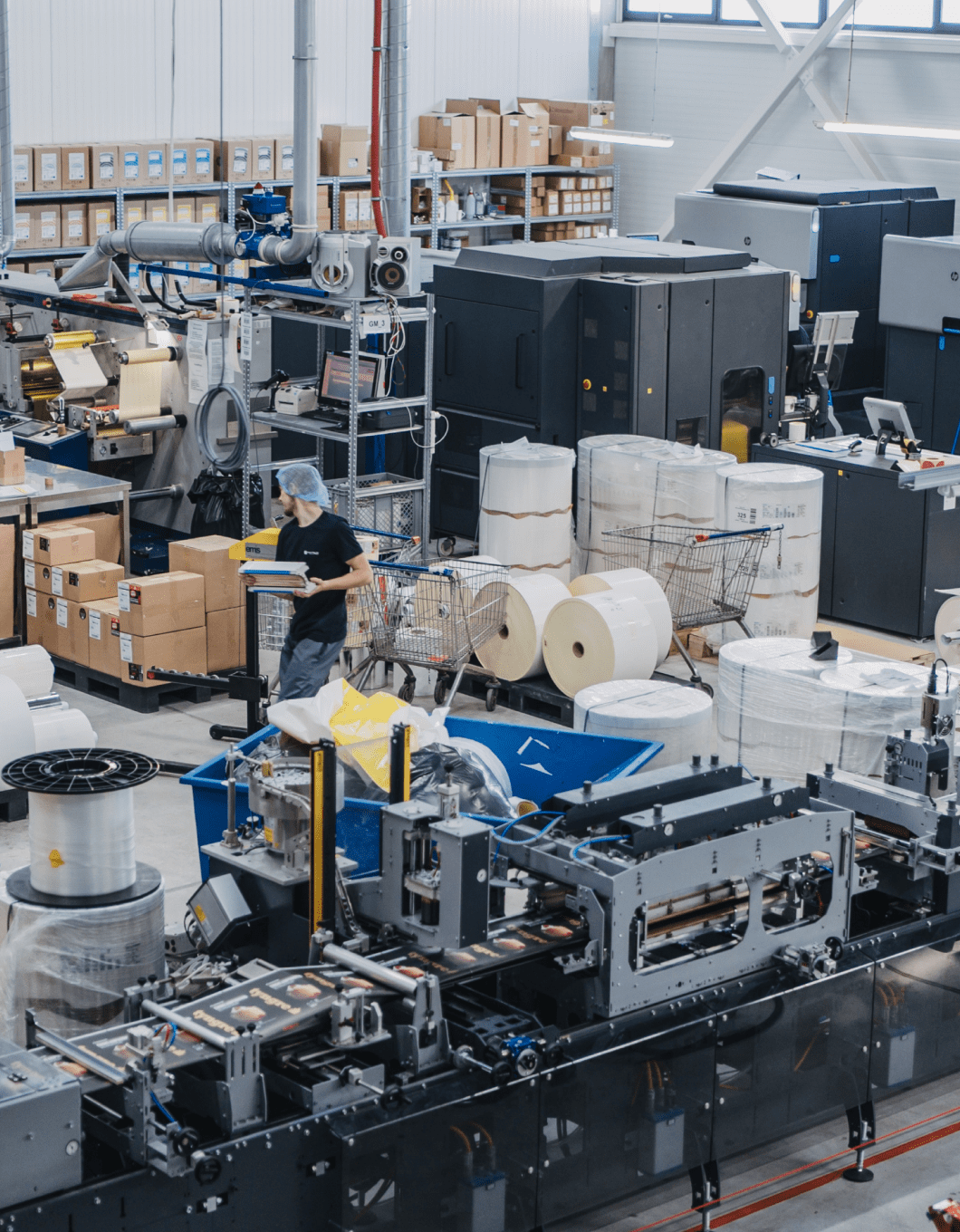

Digitally printed flexible packaging is becoming the new norm for brands. Industries and companies are constantly evolving and packaging is not an exception. It was only a matter of time before outdated conventional printing methods and ordering processes will be pushed out by digitisation and new technologies.

Conventional printing methods require printing plates to be produced first and that uses precious time and extra money. In order for the printing run to be profitable, large minimum ordering quantities are forced on the buyers. It would be no surprise to learn that you have to order at least 50.000 bags per artwork. And it takes 6-8 weeks to be produced. That has to change!

With the digital revolution situation is rapidly evolving. Now small companies and brands can have the same quality level packaging as the big ones. And big brands can benefit from other benefits from digital printing.

Let‘s identify the key differences.

Faster production times

When printing digitally, the print file is sent directly from the computer to the printing press. There is no need to prepare printing forms for each colour in the artwork, which can take days to do. Artworks can be easily modified and then it is up to you how quickly you can confirm the artwork.

Furthermore, at Lprint we have an automatic file checking system that notifies you instantly if there are any problems with your file and in some easy cases corrects the file on the fly. You see a 3D preview of your final pouch instantly and based on this information can proceed to production. What used to take from a few days now can be done in a few minutes.

Ability to print different artworks at the same time

Once again when there is no need to produce printing plates and digital printing process is quick and easy to set up with minimal waste, we are not bounded by large minimum ordering quantities per artwork. For us there is no difference if we print 2 or 200 different artworks.

If we push it a step forward, we can even customize every single artwork that you print. You can choose which artwork components stay the same and which ones can customized or generated by our software.

Easy to modify the artwork

Prints are being done straight from the file. If you have information that needs to be updated with every order, like batch numbers, best before dates, product composition this can be easily adjusted on the fly.

Order packaging on-demand

Quick turnaround of digital printing lets you react to market changes right in time. Small and medium quantites can be printed digitally without overstocking your packaging. This saves up the capital that you would have to use for your stock and of course warehouse space requirements are reduced.

Moreover, packaging requirements are changing quite often and packaging that is overstocked can become obsolete due to new regulations. As a matter of fact, brands claim that 30% of packaging gets obsolete because of this. Imagine saving this amount of money by ordering on-demand: order what you need, how much you need and when you need it.

Different artworks for every ocasion

Your packaging is now your marketing tool. Digital printing allows you to create customized product packaging for seasonal, promotional, location or event. Why not create a specific artwork that will be sold in Copenhagen during Christmas 2023? Or why not create a snack with a specific packaging for FCK and Brøndby football match, sold exclusively at the stadium?

It is a more environmentally friendly printing method

Smaller print runs produced digitally uses significantly less water and energy then packaging printed in flexography or gravure, resulting in lower CO2 emissions.

Smaller pouches introduce portion control which reduces food waste.

Ordering packaging on-demand means less obsolete packaging is being sent to landfills.

Digital printing offers opportunities that other printing methods are not capable of doing

For example, variable data printing is only possible with digital packaging printing technology.

Brands can take advantage of these opportunities by creating tailored or personalized packaging for different consumer groups (each package is different) and by customising the product’s anti-counterfeiting capabilities (micro-text printing).

This technology helps customers to improve the visibility and distinctiveness of their products on the shelf, drive consumer engagement (f.x. QR codes) and protect against counterfeiting.

Conclusion

Still not convinced? Get in toucg with us or book a free consultation with us and let’s see how you can utilise digital printing in your company. Otherwise, go to our pouch configurator and start benefiting from digitally printed pouches right now.

We understand that you might be new to questions of packaging and sustainability. And it can all get quite confusing quickly. That’s why we are happy to dedicate our time to helping you navigate through it all. Contact us for a free consultation and we’ll help you come up with the best result for your business.

You still have active cart items in this language, if you want to switch to the other language, cart contents will be deleted.

You can only reorder items that were ordered in the same language/currency combination you are currently in.