When talking with brand owners, I notice that educating one’s customers on the subject of digitally printed flexible packaging is still an issue. Even though awareness of short run prints and niche products is getting more and more attention, potential benefits of larger print jobs are still widely misunderstood and undervalued. In the upcoming few posts I’ll take deeper look into this topic, starting with supply chain efficiency.

Supply chain is constantly looking for ways to minimize waste and get the best efficiency from labor, materials and time. Digital printing can help tap into these resources mainly by reducing waste and obsolescence of packages.

Up to 40% of conventionally printed packaging can get scrapped

Due to constantly changing packaging informational requirements, shifting market trends, product testing and high minimum ordering quantities, significant quantities of conventionally printed flexible packaging gets scrapped. From the case studies that I have examined, this number can easily reach 40%.

On the other hand, digital printing can be successfully used to combat this issue.

Shorter runs, smaller batches, shorter turnaround time, printing on-demand and reacting to market shifts gives you significant advantage. In the same case studies as mentioned above, around 5% of scrapped packaging was observed. This results in more benefits too, which are:

Digital prints aren’t as expensive as you might think in the longer runs

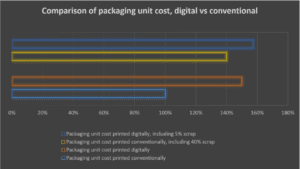

Taking these considerations into account, price difference between conventionally and digitally printed packaging gets much smaller. Furthermore, instead of calculating cost per unit produced, supply chain managers should focus on cost per unit sold.

Summary of this can be seen in the graph below. If we include capital that wouldn’t be tied in unusable or stocked packaging, supply chain efficiency can alone offset the price difference.

Next on the list is business development opportunities. Stay tuned!

We understand that you might be new to questions of packaging and sustainability. And it can all get quite confusing quickly. That’s why we are happy to dedicate our time to helping you navigate through it all. Contact us for a free consultation and we’ll help you come up with the best result for your business.

You still have active cart items in this language, if you want to switch to the other language, cart contents will be deleted.

You can only reorder items that were ordered in the same language/currency combination you are currently in.